Service

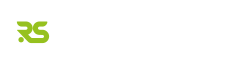

Soft Anodising:

Soft Anodising, Standard Anodising also known as Type II Anodising or decorative anodising, is a specific electrochemical process used to create a protective oxide layer on the surface of aluminium and its alloys. This process is commonly used in various industries to improve the corrosion resistance, durability, and appearance of aluminium components.

Service

Hard Anodising:

Hard Anodising, also known as hard coat anodising or type III anodising, is an electrochemical process used to produce a thick and durable oxide layer on the surface of aluminium or other metals. The resulting hard anodised coating provides increased hardness, wear resistance, corrosion resistance, and electrical insulation properties.

Service

Iridite Finish: Coming Soon

Iridite finish, which is a type of chemical conversion coating, is a surface treatment process primarily used for aluminium and other non-ferrous metals. It is commonly employed to improve these metals' corrosion resistance, electrical conductivity, and paint adhesion properties. Iridite is a brand name for a specific type of chemical conversion coating, and it is often used interchangeably with other terms like chromate conversion coating or alodine, which are generic names for similar processes.

lanthane aluminate or lanthanum aluminate is a type of ceramic material that can be used in thermal barrier coatings. It is known for its high-temperature stability, thermal shock resistance, and chemical durability. lanthanum aluminate-based coatings have been investigated and used in high-temperature applications, including tbcs.

Service

Conversion Coating: Coming Soon

Conversion coating is a surface treatment process used to improve the properties of metal surfaces, particularly those made of aluminium and other non-ferrous metals. This process involves the chemical transformation of the metal's outer layer, resulting in enhanced corrosion resistance, improved paint adhesion, and other desirable characteristics. Conversion coatings are widely used in various industries, including aerospace, automotive, electronics, and manufacturing. There are different types of conversion coatings, each with its specific benefits and applications.

Service

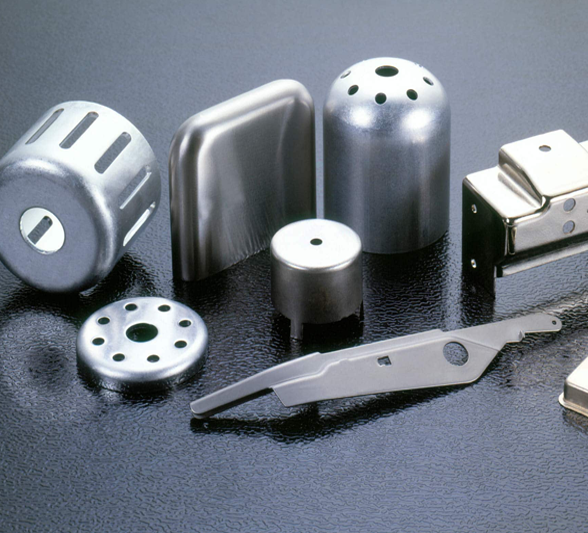

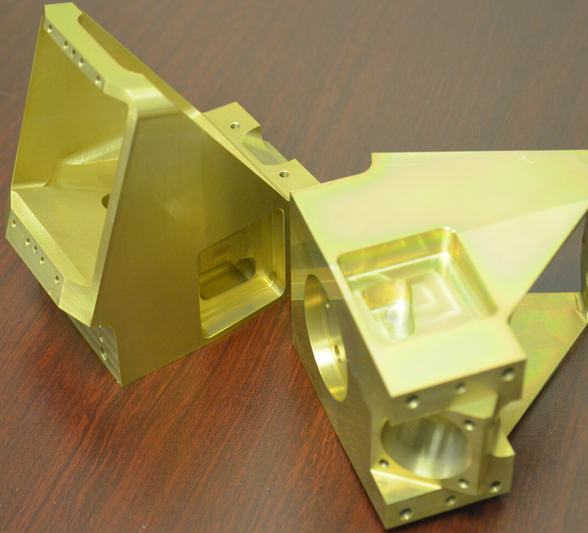

Masking And Bunging Of Components:

We can offer masking of parts where the finish is not required for example masking holes to prevent dimensional change where tolerance is critical. to mask areas on aluminium during anodising to maintain a conductive surface.

Useful Information:

it is worth noting that once anodised the surface of the metal does not conduct electricity therefore should your parts require conductivity you will need to state this and where the contact points are so we can mask the parts appropriately beforehand.

The same applies to internal threads where the tolerance is critical as the anodising process will add to the size therefore we can mask these threads if made aware upon ordering.

for certain applications e.g. if parts are going to be used in a marine atmosphere where corrosion resistance is more important than decorative purposes it is most suitable to have parts hard anodised.

note; the above should be taken as a guide