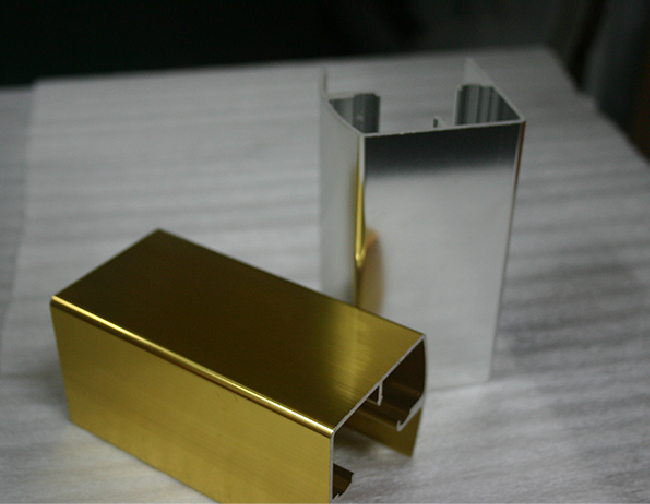

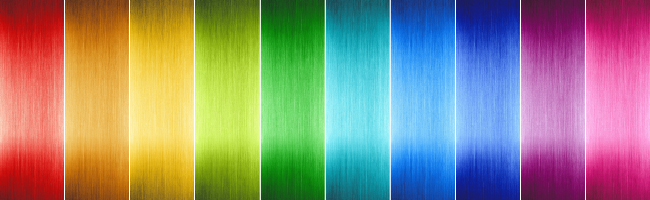

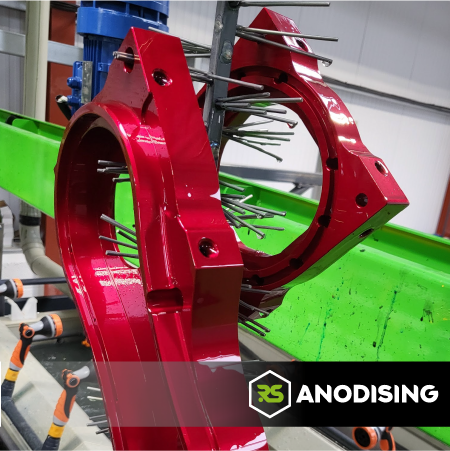

Colours

Anodising offers various colors, from clear to black, blue, green, gold and red. This can be achieved through dyes for enhanced aesthetics, and functional properties to suit various customer specifications.

Water Treatment

Water Treatment is an essential aspect of the anodising process to ensure the quality of the final product and maintain the efficiency of the anodising

Quality

The quality of our work has to be paramount. It defines our reputation, customer satisfaction and commitment to excellence.

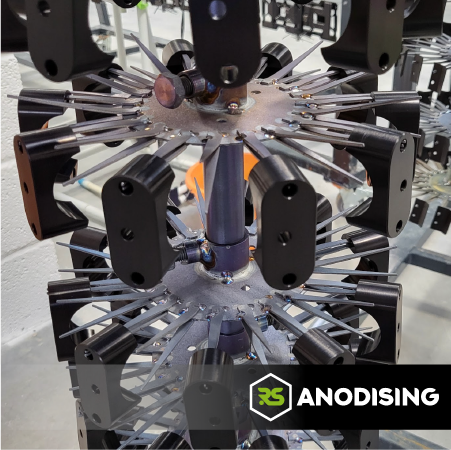

Main Services:

RS Anodising offers a fully automated soft and hard anodising line that can process parts up to 2.4 m in length, 0.9 m in depth, and 0.6 m in width. We can also dye after anodising to the same measurements.

Soft Anodising

Soft anodising is a milder electrochemical process that creates a thin, protective oxide layer on aluminum, improving its appearance, corrosion resistance, and surface finish for less demanding applications.

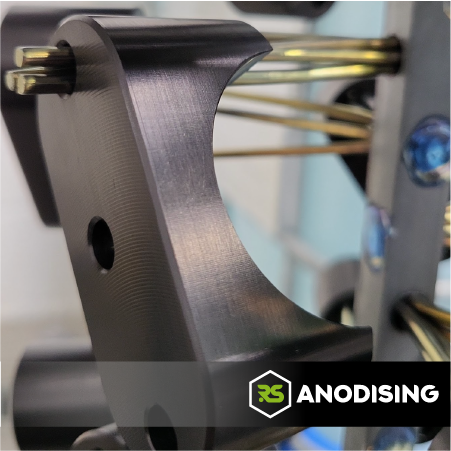

Hard Anodising

Hard anodising is an advanced electrochemical process that thickens the natural oxide layer on aluminum, enhancing its hardness, corrosion resistance, and durability for demanding applications.

ISO 9001 & ISO 14001

ISO 9001 ensures quality management, while ISO 14001 emphasizes environmental responsibility, together enhancing operational efficiency, customer satisfaction, and sustainability for businesses.